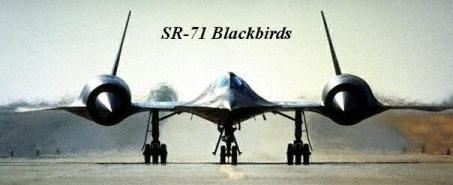

Blackbird Construction

Lockheed Advanced Developments Projects

Flip Book Java Applet Consisting of 50 Images

Please wait, the applet is momentarily loading

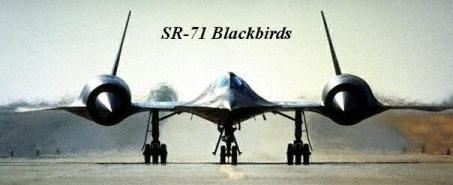

These

images show the construction of the Blackbirds; A12; YF12A and the SR-71 at the Lockheed

Skunk Works plant in Burbank, California in the early 1960's. Kelly Johnson,

designer of the Blackbirds and his prestigious crew of engineers set out to

design and build perhaps the most remarkable aircraft in aviation history.

Working with Titanium, a metal that had desirable characteristics for the high

heat environment of Mach Three flight, proved in itself to be a daunting

challenge. The metal had never been forged in large quantities and the quality had

to meet strict controls for consistency. In addition, the US had to import the

metal indiscreetly from the largest source in the world; the USSR. The landing

gear on the SR-71 is the largest single piece of forged Titanium. Other segments

of forged Titanium was made oversize and then milled to exact tolerances for

stringers, fuselage and wing construction. At the end of construction almost 90%

of the Blackbirds material consisted of Titanium. Stainless steel was used for

hydraulic and fuel lines. From the ground up the Blackbirds were designed to

withstand the 900+ degree temperatures on the surface skin at Mach three or

better. There were expansion joints in almost all fittings as the aircraft grew

several inches from the high heat generated. To make the aircraft stealthy,

plastic composite panels shaped like a triangle were inserted on the outer

perimeter of the wing surfaces. There were alternating titanium and composite plastic

wedges designed to break up the incoming radar signals. Rudders were canted

inward for the same reason. The paint consisted of minute iron ferrite balls and

the cost per quart of Blackbird paint was nearly $400. Needless to say, the

entire aircraft was not regularly repainted but rather spot painted as needed.

Exotic alloy metals such as Hasteloy X and ceramics were used in the

construction of the Pratt & Whitney J-58 engines. Temperatures in the

afterburner sections reached 3200 degrees Fahrenheit.

These

images show the construction of the Blackbirds; A12; YF12A and the SR-71 at the Lockheed

Skunk Works plant in Burbank, California in the early 1960's. Kelly Johnson,

designer of the Blackbirds and his prestigious crew of engineers set out to

design and build perhaps the most remarkable aircraft in aviation history.

Working with Titanium, a metal that had desirable characteristics for the high

heat environment of Mach Three flight, proved in itself to be a daunting

challenge. The metal had never been forged in large quantities and the quality had

to meet strict controls for consistency. In addition, the US had to import the

metal indiscreetly from the largest source in the world; the USSR. The landing

gear on the SR-71 is the largest single piece of forged Titanium. Other segments

of forged Titanium was made oversize and then milled to exact tolerances for

stringers, fuselage and wing construction. At the end of construction almost 90%

of the Blackbirds material consisted of Titanium. Stainless steel was used for

hydraulic and fuel lines. From the ground up the Blackbirds were designed to

withstand the 900+ degree temperatures on the surface skin at Mach three or

better. There were expansion joints in almost all fittings as the aircraft grew

several inches from the high heat generated. To make the aircraft stealthy,

plastic composite panels shaped like a triangle were inserted on the outer

perimeter of the wing surfaces. There were alternating titanium and composite plastic

wedges designed to break up the incoming radar signals. Rudders were canted

inward for the same reason. The paint consisted of minute iron ferrite balls and

the cost per quart of Blackbird paint was nearly $400. Needless to say, the

entire aircraft was not regularly repainted but rather spot painted as needed.

Exotic alloy metals such as Hasteloy X and ceramics were used in the

construction of the Pratt & Whitney J-58 engines. Temperatures in the

afterburner sections reached 3200 degrees Fahrenheit.

Over the course of 25 years, the SR-71 and sister ships, the A12 and the YF12A have provided the United States and the free world with intelligence gathering that is second to none. Although the Blackbirds are now retired and relegated to museums, she lives on in the hearts and minds of those that built, flew and maintained the world's fastest jet aircraft. Remember though that Lockheed Martin Corporation and other aviation manufacturers are not sitting on idle hands, nor have they ever lost sight that world peace demands vigilance.

Leland Haynes, Webmaster, SR-71 Blackbirds

Credits:

Images provided by Lockheed Martin Corporation and Lockheed Photographer, Tony Landis.

Webpage HTML and

formatting by Leland Haynes, Webmaster, SR-71 Blackbirds. All content is

copyrighted on July 09, 2003 and may not be reproduced in any format including

electronic retrieval. Flip Book Applet provided by Anfyteam at this URL: http://www.anfyteam.com/

Credits:

Images provided by Lockheed Martin Corporation and Lockheed Photographer, Tony Landis.

Webpage HTML and

formatting by Leland Haynes, Webmaster, SR-71 Blackbirds. All content is

copyrighted on July 09, 2003 and may not be reproduced in any format including

electronic retrieval. Flip Book Applet provided by Anfyteam at this URL: http://www.anfyteam.com/

| SR-71 Front Page | Links Page | Index Page | Recollections | 2001 Reunion |

| "SR-71 Blackbirds" Web Site Navigator | ||||

| First Created: April 15, 1996 - Last Revised: March 29, 2004 | ||||

| Copyright © 1996 Leland R. Haynes Email: sr71webmaster@sr71.us | ||||

Page #151 of the SR-71 Blackbirds

![]()